It’s 1981 and at the Wolfsburg factory a camera crew is following the production of a Mk1 Golf. Today, they still manufacture Golfs at Wolfsburg so as we gear up to give away a trip to the six square kilometre facility in our special Wolfsburg VIP competition we though it we’d take a nostalgic look back at how the original Golf was made…

The story starts at 4.03am as a freight train loaded with sheet metal coils arrives at the giant Volkswagenwerk in Wolfsburg. Meanwhile, a train bringing additional components from VW’s other sites along the Mittelland Canal; the Golf’s engine arrives from Salzgitter, its transmission from Kassel, its axle and steering from Braunschweig. As they make their way slowly along the rail network that criss-crosses the site – there’s 69km of railway in total – a lorry turns into the plant loaded with headlights, alternators and other components. Radiators arrive from France, tyres from the UK and a stack of wiring harnesses from the former Yugoslavia.

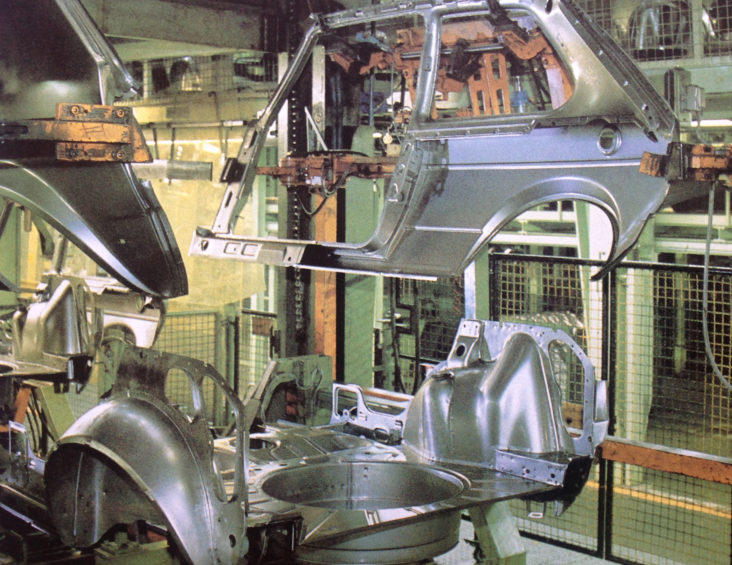

By 5.30am, the first body pressings are being made. VW’s press shop – the size of 65 football pitches – was producing over 4000 different stampings at that time. ‘Robby’ robots get busy with the welding process and by 6.20am the first finished shells make their way to the body assembly shop, while other components make their way along the 190km long network of chain conveyors which ensure everything is to hand when needed. Some more historic stats for you – in 1981, the factory had 32km of outdoor roads, 36km of indoor roads, 160 tractors, 1,000 trailers and 425 fork lift trucks moving 12 million parts within the factory. And that’s just for one model.

The Golf receives its code plate (the factory could build 3,600 different versions of the same basic Mk1 Golf bodyshell). By 8.15, the side panels, roof and floor have been introduced to the main body, rear section and wheel houses to form a complete shell. A Golf body shell is produced every 16 seconds, which equates to 3000 a day.

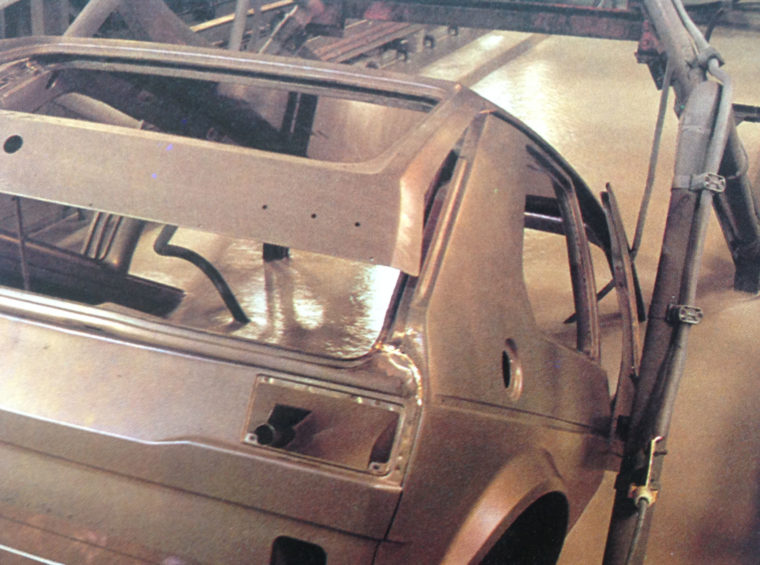

At 11.40 it goes to the paint shop. First it gets a hot shower to remove grease, dirt and metal filings before being dried and given its first matt grey undercoat. It’s washed again in desalinated water before being dipped into the electrocoating (a relatively new process back then) immersion tank. The body enters at an angle so air can escape from all the cavities. The concentration is 10% and 90% water. When dry, it’s washed again, dried by a blower and the primer is baked on during a 25 minute trip through the 180 degree Celsius kiln tunnel. Some areas are sanded by hand at this point would you believe.

To make sure everything’s watertight and to protect against rust, the body is then sealed with PVC, dried, sealed again, sprayed by hand again in places and kiln dried. Dust is removed with special dust-trapping cloths. At 14.58 the shell receives its final coat of paint, applied by hand initially with the inside and tricky to reach areas covered first, before being painted by complex automatic spraying kit. It’s baked for 30 minutes at 140 degrees C. After being inspected, cavity wax goes into the doors, bonnet and underfloor.

By 16.00 the bodyshell has entered the final assembly line where one of the factory’s ‘punchcard’ IBM computers has worked out its exact specification. A hectic activity ensues fitting bumpers, lights, interior – and of course, the powerplant. Wiring looms go in and oil and fuel are added so it can be driven for the first time. Wheel alignment is carried out at this stage, too, and all the necessary nuts and bolts are automatically tightened to the correct torque settings, the final check, unbelievably, being carried out by hand with a torque wrench!

It’s 20.00 now and it’s almost the end of this Golf’s journey. All that’s left is to put it on the dynamometer to check all is as it should be engine wise. Forty minutes later, having gone through a wax spray booth at the end of the production line, a thick coat of bitumenized wax is applied to the underside and a further thick coat of wax protects the bodywork until it reaches the customer. In order to complete the final part of its journey, the Golf is loaded onto a train and onwards to its lucky first owner…

Back in 1981, 2,000 Golfs were made every day at Wolfsburg. Today, total car production (Golf, Touran, Tiguan) is only 3,800 – so they must have been going some back then. But get this, in 1966 Wolfsburg produced over 6,700 vehicles every day, at a production rate of one car every 11 seconds. The factory employed 92,000 people in ’66, while today just 73,730 work there.

No doubt there’s a hundred and one other useless bits of information about Wolfsburg and its factory we could tell you, like the fact that the town had its own purpose built housing for workers back in the 1950s, the instantly recognisable Beetle shape can be seen virtually everywhere you go and in the mid-sixties it had more cars, and more children per capita than any other German city. Oh, and that those landmark smoke stacks are nearly two and a half times higher than Niagara Falls.

Or, perhaps if you win our competition – which closes December 31 – and get to visit for yourself, you’ll be able to tell us! You can enter here.

Ian

The opinions expressed here are the personal opinions of the author and do not necessarily represent the views and opinions of VW Heritage